Mini 3 & 5 Layers Co-Ex Blown Film Line

WORLD’S SMALLEST POLYMER PROCESSING LINES

The amazing Ultra Micro Series

Stainless Steel & Transparent Acrylic top Barrel Cover & Hopper

New Ultra Micro 3-Layers, 3 Extruders Co-Ex Chill Roll Line

THE ULTRA MICRO FILM BLOWING LINE

THE ULTRA MICRO CHILL ROLL LINE

ULTRA MICRO SINGLE SCREW PELLETIZING LINE

Designed by our engineers to reproduce larger lab and production lines based on our Ultra small extruder with conical screw that can be used with regular pellet sizes

Computerized Screen

Combi Film Blowing & Chill Roll Line with 1 Common Extruder

Extruders

Ultra Micro 3-Layers Co-Ex Blown Film Line with 3 Extruders

MINI CAST FILM

SINGLE LAYER TYPE LMCR-150 & MULTILAYER TYPE LMCR-150 COEX

Our New Scientific Mini Single-Layer Film and Sheet Line Type LMCR-150 has been developed to fill the gap of supplying a very compact and economic cast film and sheet line for laboratory applications.

The chill roll attachment is designed to produce a maximum untrimmed layflat width of 125 mm. It is equipped with a mini single-screw extruder having a 16 mm screw diameter and a long L/D ratio of 30 designed to easily process a very large variety of plastic resins and of regular pellet shapes. The flat film and thin sheet die has a streamlined 90-degree die adapter with a produced film or sheet width of approximately 115 mm. The rubber haul-off nip-roll is driven by a servo motor giving a very steady and even pull of the film and sheet from the chill roll. The film is collected in an expandable air shaft wind-up unit which is also driven by a servo motor.

The chill roll attachment is designed to produce a maximum untrimmed layflat width of 125 mm. It is equipped with a mini single-screw extruder having a 16 mm screw diameter and a long L/D ratio of 30 designed to easily process a very large variety of plastic resins and of regular pellet shapes. The flat film and thin sheet die has a streamlined 90-degree die adapter with a produced film or sheet width of approximately 115 mm. The rubber haul-off nip-roll is driven by a servo motor giving a very steady and even pull of the film and sheet from the chill roll. The film is collected in an expandable air shaft wind-up unit which is also driven by a servo motor.

Barrel

Flat Die

Wind Up

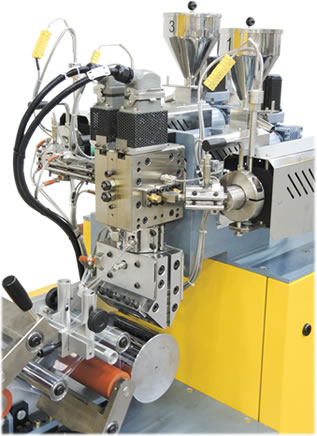

MINI THREE-LAYER FILM AND SHEET LINE TYPE LMCR-150 CO-EX

Our New Scientific Three-Layer Min i Cast Film and Sheet Line Type LMCR-150-COEX is a latest addition to Labtech’s Mini Machine Lines. This Mini Cast Film Co-Ex Line have installations of mini-sized hoppers, extruders, die, feedblock, chill roll, rubber nip rolls, edge-trimmer, cassette wind-up and film wind-up. The whole chill roll assembly is mounted on a bench cabinet while the extruders are mounted on an elevated base of the same bench cabinet. The chill roll attachment is designed to produce a maximum untrimmed layflat width of 100 mm.

The line occupies a minimum floor space of 1.7 m x 1 m and height of 1.4m. The sub-cabinet has a sliding base to hold all the electric components inside.

The line occupies a minimum floor space of 1.7 m x 1 m and height of 1.4m. The sub-cabinet has a sliding base to hold all the electric components inside.

Flat Die with 3 Layers Feed Block

MINI BLOWN

Single Layer Type LMF-200 & Multilayer Type LMF-200 CoEx

MINI 3 & 5 LAYERS CO-EX BLOWN FILM LINE

Our latest development of a very practical, economic and compact Mini Scientific Co-Ex Film Blowing Line available in 3 layer 3-extruder version, as well as 5-layer 5-extruder version.

- mini 16 mm single-screw extruder

- loss-in-weight hopper feeders

- 360° oscillating haul-off unit

- pneumatic nip rolls

- 3 or 5 layers pancake die

Mini Single-Layer Blown Film Line

Our New Scientific Mini Single-Layer Blown Film Line is a viable low-cost alternative to our regular blown film lines.

- mini 16 mm single-screw extruder

- single-layer blown film spiral mandrel die

- annular die lip diameter of 25 mm

- compact film blowing tower

Electrical Components

Electrical components are neatly kept below the bench subcabinet with a sliding base