16 MM Twin Screw Extruder with Water Bath & Pelletizer

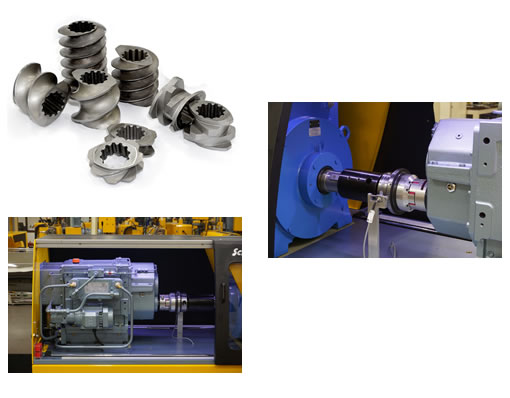

TWIN SCREW EXTRUDERS WITH Ø 12 AND 16 MM

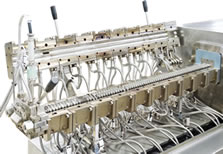

With Modular Barrels for Optimum Flexibility

12 MM Twin-Screw Extruder

16MM Twin Screw Extuder Powder Coating Line

16 Twin Screw Extruder with Downstream Water Bath & Pelletizer

- clamshell barrel

- up to 52 L/D length

- standard temperature 400°C

- screw speed 800 RPM

- drive power 2.2 kW

- gravimetric feeders

- side feeders for 16 mm twins only

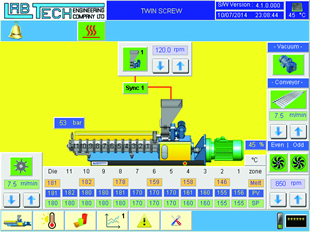

- manual or fully computerized touch screen controllers

TWIN SCREW EXTRUDERS WITH Ø 20 AND 26 MM

With Modular Barrels for Optimum Flexibility

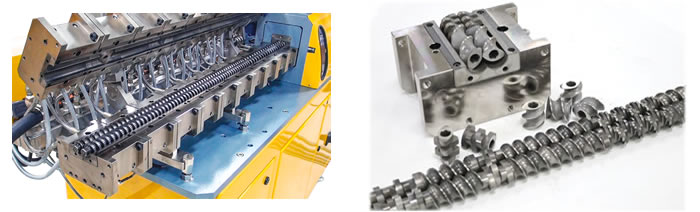

Modular Co-Rotating Twin-Screw Extruders are available with clamshell barrels and our unique high tool steel barrel inserts with screw diameters of 20 and 26 mm have L/D ratios of up to 60. These extruders are suitable for laboratory, research, and small batch productions. The single elements are mounted on hexagonal shafts of screws for optimum flexibility of screw configurations.

Modular Co-Rotating Twin-Screw Extruders are available with clamshell barrels and our unique high tool steel barrel inserts with screw diameters of 20 and 26 mm have L/D ratios of up to 60. These extruders are suitable for laboratory, research, and small batch productions. The single elements are mounted on hexagonal shafts of screws for optimum flexibility of screw configurations.Extruders are available with both single and twin-screw hopper feeders, vacuum pumps with multiple vent outlets on the barrel, twin-screw side feeders, liquid feeders, quick screen changers, and a multitude of screw element types and combinations.

26 mm MaxiCompounder with 22 kW drive motor and 1200 max screw RPM

Optional Computerized Controller Equipped with LCD Touch Screen

26 MM Twin Screw Extruder Modular Barrel Section

TWIN SCREW EXTRUDERS WITH Ø 26 MM

With Co- and Counter-Rotating Twin Screw

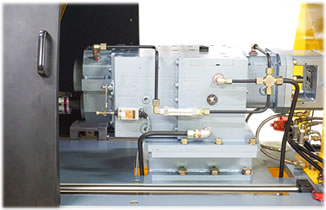

The standard twin has a drive power of 15 kW and a max screw RPM of 400 for Counter-Rotating and 800 for Co-Rotating. It has a re-designed high torque gearbox comprising of additional shaft supporting gears, and a direct drive gear pump for closed-loop forced oil lubrication and cooling.

TWIN SCREW EXTRUDERS WITH Ø 36 MM

With Modular Barrels for Optimum Flexibility

The New High Output 36 MM Twin Screw Extruder

Both the Standard and the Maxi36Compounder can be equipped with an induction motor or water-cooled motor drive with a high-torque gearbox having a motor-driven gear pump for closed-loop forced oil cooling system.

additional side or top feeders.

TWIN SCREW EXTRUDER PHARMACEUTICAL

5 Sizes with Ø 12, 16, 20, 26 and 36 MM

Designed for Optimum Production Of Pharmaceutical Compounds

Built According to GMP Standards

Pharmaceutical Modular 26 MM Twin Screw Extruder

Our Pharmatech Co-Rotating Twin-Screw Extruders are made with a complete modular buildup of the clamshell barrel. The compounder is available in 12, 16, 20, and 26 mm and barrel lengths from 25 to 40 L/D and with an AC vector motor drive.

Pharmaceutical Modular 12 MM Twin Screw Extruder Line

The extruder is supplied with a stainless steel gravimetric hopper feeder type LGF 80 TS complete with hopper unit with a “spiral type” twin feed screws and a stirring arm (agitator) above the feeding screws, DC motor port.