CO EX CHILL ROLL LINES

with up to 9 layers of Cast Film

MDO unit in-line with a co-ex cast film line which is equipped with two edge-cutting stations positioned before the MDO

unit and the other at the wind-up station.

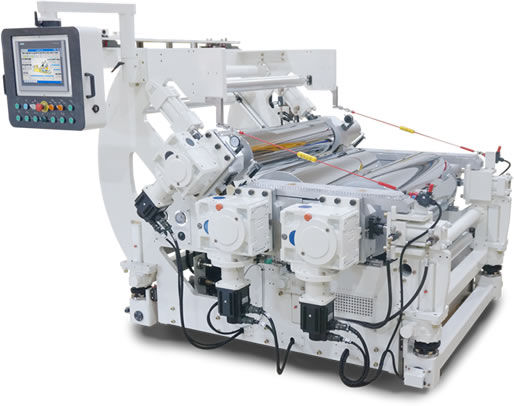

MDO Film Stretching Attachment

Also available with in-line or off-line MDO film stretching attachments. Single and 2-Station MDO units with roll widths from 300 to 800 mm.

Medium Economy Size Chill Roll

Heavy Duty Chill Roll Lines with 300 Roll Width

Heavy Duty Chill Roll Lines with 300 to 400 Roll Width

Extruders

Feedblocks

Manifold Die

NEW LARGE SIZE HIGH-SPEED CO-EX LINE

Featuring the Downstream MDO Attachment

NEW LARGE SIZE 3/5 LAYERS CO-EX CHILL ROLL LINE

The line will be used for a multitude of polymers from polyolefin to more advanced thermoplastics like PET etc. It is equipped with two single screw extruders and one twin, feed block, die and a new design of a chill roll attachment with large 600 mm diameter rolls. Downstream the line has a new large vertical MDO unit as well as a wind up unit with automatic change over of the film rolls.

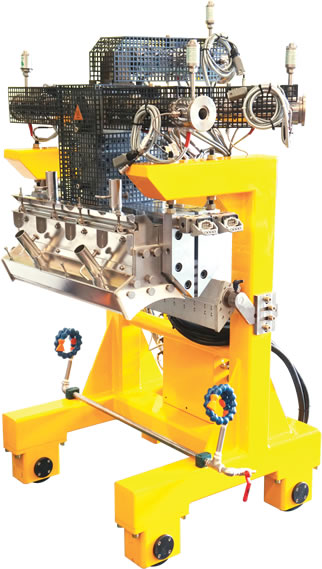

C-Type Chill Rolling Stack

Single to 5 Layers Lamination C-Type Chill Roll Line

NEW SINGLE TO 5-LAYER LAMINATION C-TYPE CHILL ROLL LINE

The newly developed design of the Cast Film Lamination Line of Labtech Engineering can laminate up to 5 layers and consists of a 60 mm single-screw extruder, a C-type chill roll stack, 2 unwinders at the front, 1 unwinder at the rear, and 1 unwinder at the top of the platform. The lamination line is also equipped a 3-zone coat-hanger flat die with vacuum blower and static edge-pinner, a rotary-knife edge-cutter with edge-trimmed cassettes and a wind-up.